B-1000 850 Belt

ENABLING YOU TO PROCESS MORE FOR LESS

THE WORLDS MOST POPULAR PEF SOLUTION WITH ALMOST 100 INSTALLATIONS WORLDWIDE

Belt-Range PEF Processing

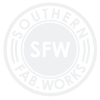

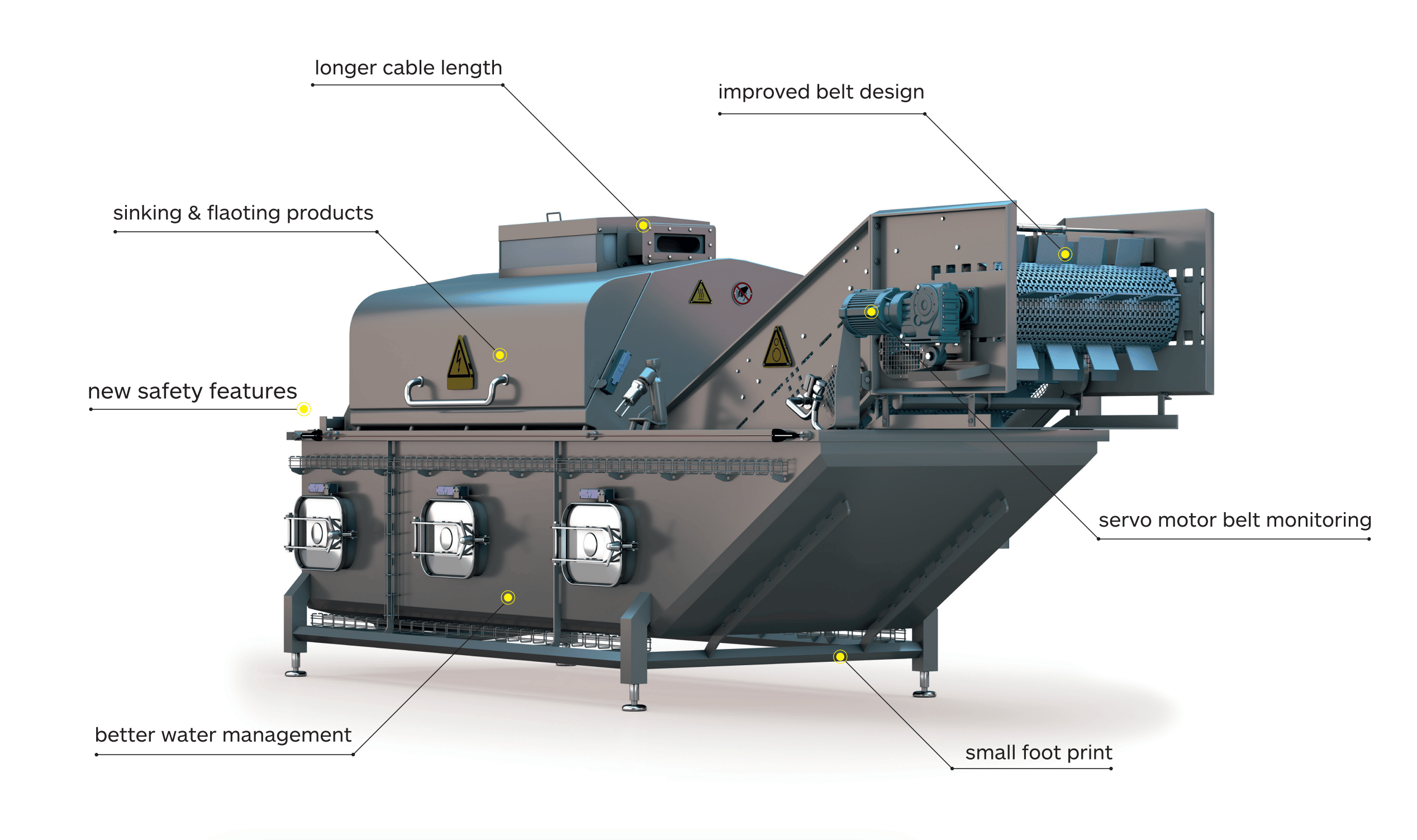

Introducing our new B1000-850 system design, the highest capacity belt system to date. With all safety features included into the belt vessel, the design enables processing of up to 100 T/H with a compact, easy to install footprint. The largest free cross section on the market and optimized product in- and outfeed allow high product to water ratio with only generator required. Other new features include new pulsed power connections with extended cable length, a range of belt types

with enhanced belt lifetime, integrated belt motoring, improved water management and cleaning. The design is fully suitable for sinking and floating products. Available options also include split belt options for multiple products, anti-foam dosing and automated conductivity control.

Packed With New Features

Robust and Customisable

The Belt-Range system is built with efficiency and down-time in mind. It is built to last under the toughest conditions and can be fully customized to your use.

By giving our customers full control over the treatment parameters, it means they can reach the best product for them and their customer base. We will also work with you to fully integrate this into your current processing line.

Installation and Training

Introducing a new machine to your processing can be a big step but, our engineers are here to help train your staff and maintenance to give you and your team full understanding of how to operate your new Belt-Range System. We also have a full support team ready to help you at a moment’s notice.

If you’re unsure whether a PEF system can help you, we have trial halls and can even do a trial on site with Food Physic’s professional team.

USA

info@food-physics.com

(208) 375 4121

8512 West Elisa St,

Boise, Idaho, 83709

UK & IRELAND

info@food-physics.com

+44 7766 406 363

Woodham Lodge, Bicknacre, Chelmsford,

Essex, CM3 4HG