Revolutionizing dried product quality

pEF drying

Brighter color, improved flavor, aroma and form stability

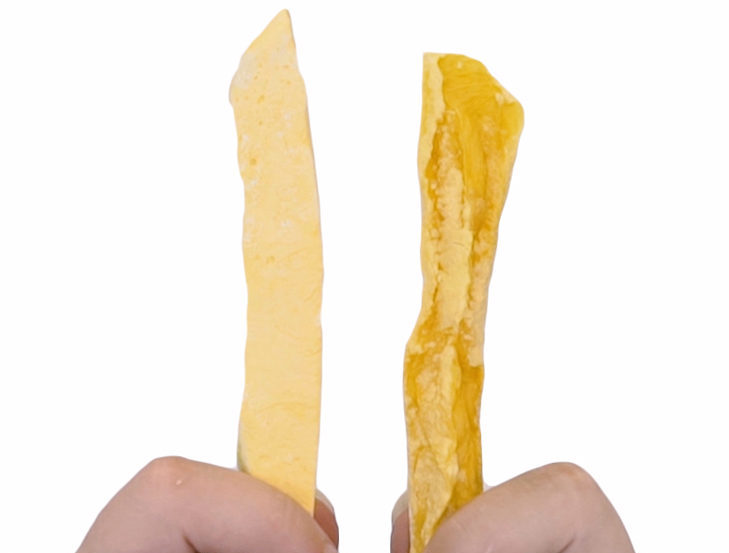

PEF vs Untreated Carrot

Changing the conventional dried produce market with PEF

Drying with Pulsed Electric Field

With PEF drying we can generate and accurately measure significant increases for retention of colour, flavour and aroma.

Form stability, rehydration and yield are also retained to a much improved level. This applies to various forms of drying including hot-air, freeze, vacuum, microwave and infra-red drying, etc.

Changing the conventional dried produce market with PEF

Drying with Pulsed Electric Field

With PEF drying we can generate and accurately measure significant increases for retention of colour, flavour and aroma.

Form stability, rehydration and yield are also retained to a much improved level. This applies to various forms of drying including hot-air, freeze, vacuum, microwave and infra-red drying, etc.

PEF vs Untreated Carrot

Greater yield, higher line capacity and energy savings with PEF

PEF Enhances Mass Transform Improving Evaporation

PEF treatment gently opens the products cell membrane, increasing internal diffusion. Treatment with the SmoothCut™ system enhances mass transfer, improving evaporation, line capacity and energy savings.

In some cases, you are barely able to notice that the fruit or vegetable has been freeze dried due to the structural integrity each raw material maintains after using PEF as a pretreatment.

PEF VS untreated raspberry

Disrupting Convention With PEF Dried Produce

1

Better Form Stability

PEF improves form stability. PEF dried products retain more of the natural characteristics of the raw material.

2

Retained Natural Flavor

PEF retains more of the natural flavor found in raw materials. Improve the flavor of your dried products with PEF.

3

Brighter Color

PEF maintains brighter colors for dried produce. PEF dried products have a recognizably brighter color compared to non treated products.

4

Energy Saving

PEF enhances mass transfer, improving evaporation, leading to increased energy savings and line capacity.

5

Better Aroma

PEF dried products retain more of the natural aromatic properties found within the fresh ingredients.

6

Increased Re-Hydration

PEF improves form stability creating a more open cell structure resulting in better re-hydration. Perfect for soups, teas and museli.

Improving products and building partnerships

Food Physics and Drying

With our benefits on dried produce in mind, Food Physics will seek to create value in all its forms throughout the dried produce industry. We are currently in the preliminary stages of drawing up partnerships to further aid dried produce manufacturers.

This is an area we think is suitable for development with PEF, backed up by our extensive research and development

USA

info@food-physics.com

(208) 375 4121

8512 West Elisa St,

Boise, Idaho, 83709

UK & IRELAND

info@food-physics.com

+44 7766 406 363

Woodham Lodge, Bicknacre, Chelmsford,

Essex, CM3 4HG